Automation and AI May Remedy Your In-plant’s Staffing Woes

"The time savings — I don't even think it's calculable.”

That’s what Tom Licata says about the automation he’s implemented as Print Shop supervisor at Rochester City School District.

When Licata started at the Rochester, New York in-plant, the bookbinding situation was highly inefficient.

“If somebody wanted a book, really their only option was a spiral coil bound, or we would have two foot-pedal-controlled … staplers,” he says. “We used to have to fold the signatures and then put them on this thing and push the foot pedal to put a staple. And you'd have to do it twice if it was a saddlestitch booklet.”

Now, the shop has an array of Konica Minolta machines: two 1100s, a 7090, a 1250, and a 7136 — complete with saddlestitching, hole-punching, and perfect-binding capabilities. With these features, all an operator needs to do is send the file and hit print.

Not only can the operator work on something else in the meantime, but perfect binding is a brand-new offering for the in-plant, which Licata says brings new work, such as workbooks.

Adding automation is one way in-plants like Licata’s are combating staffing shortages. Automation is an especially critical tool to fill in skill gaps, as preliminary data from a forthcoming In-plant Impressions report reveals nearly a third (29%) of in-plants aren’t fully staffed. Plus, more than half of those understaffed in-plants (59%) don’t have the OK from their parent organization to fill at least one of their open roles.

Automating Book Production

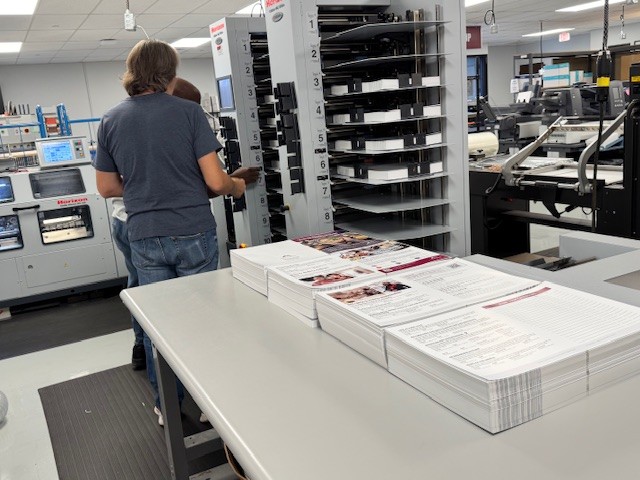

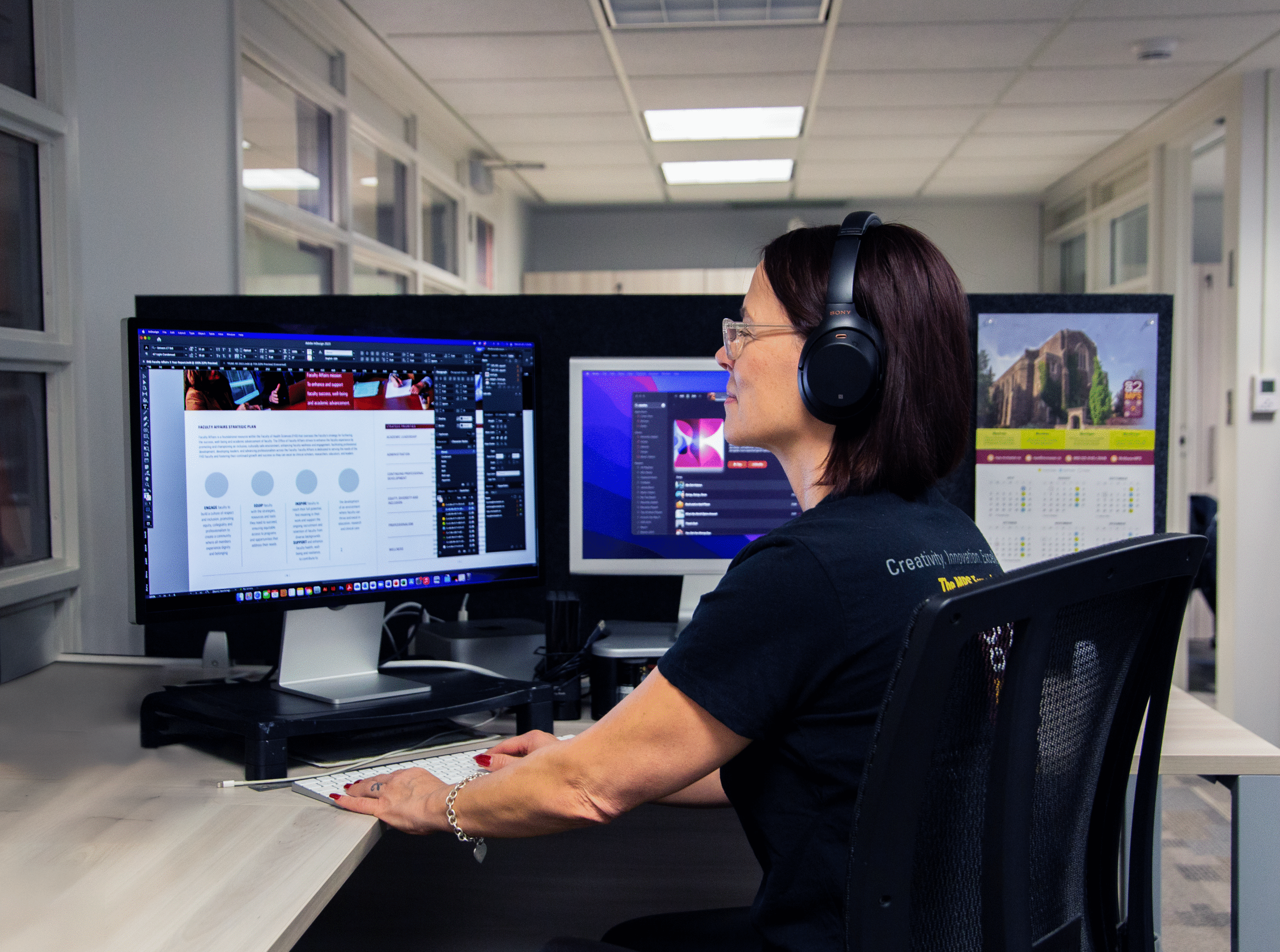

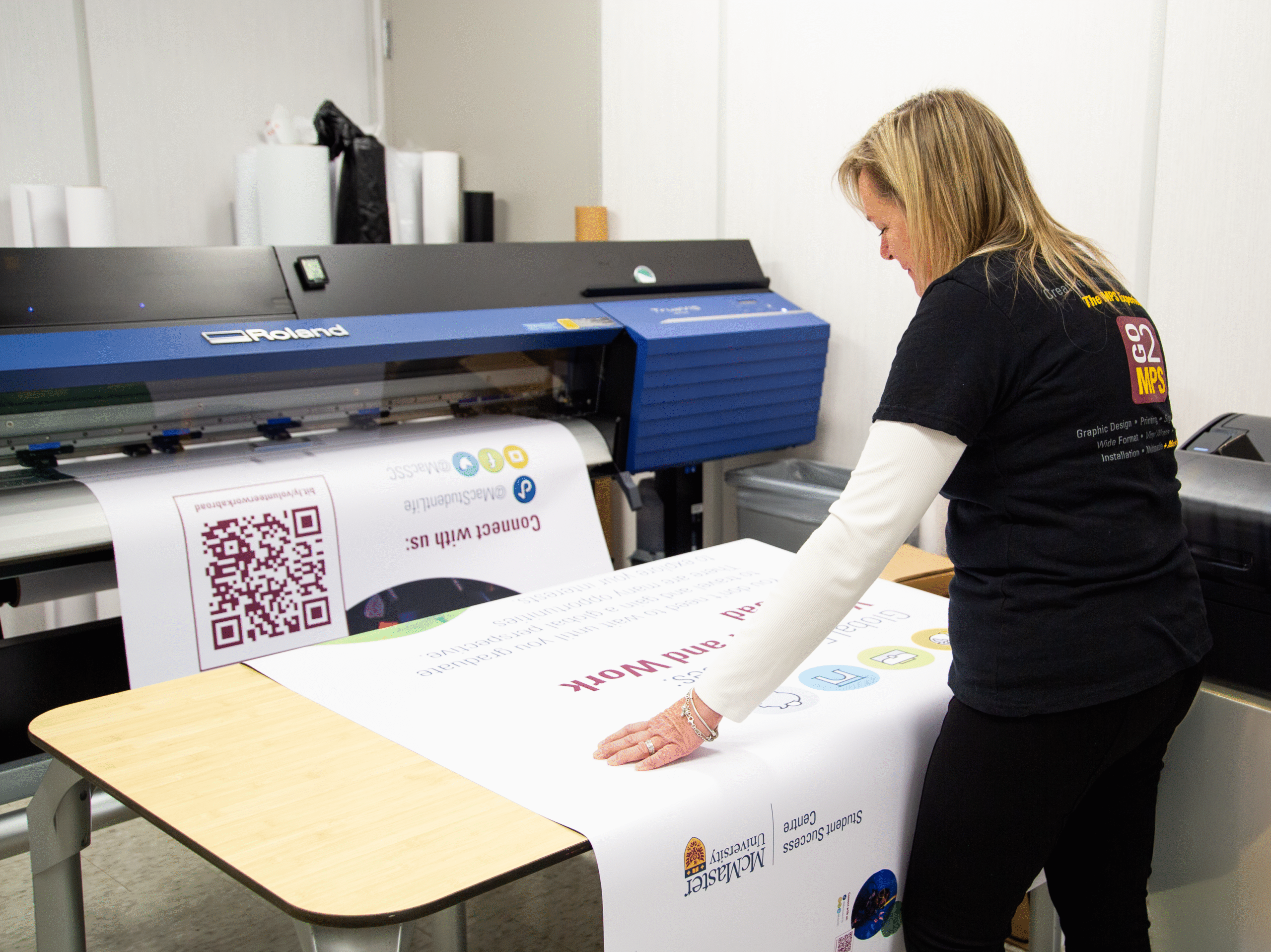

Thirteen years ago, Phil Poelmans found himself in a similar situation to Licata’s when he became director of Media Production Services at McMaster University in Hamilton, Ontario, Canada. At that time, the shop was primarily an offset shop.

“Imagine if one person wasn’t in one day, or one of the pieces of equipment didn’t work that day,” Poelmans says. “What happens to your overall production? You pretty much come to a standstill.”

One of the first things Poelmans did was swap the offset presses for a fully digital workflow to automate book production.

“You send a file to the printer, it’ll print, collate, fold, stitch, do a trim all the way around the book, and a finished book comes out of the other end,” he says. “What used to be maybe five or six people in a workflow is two now.”

From Tedious to Touchless

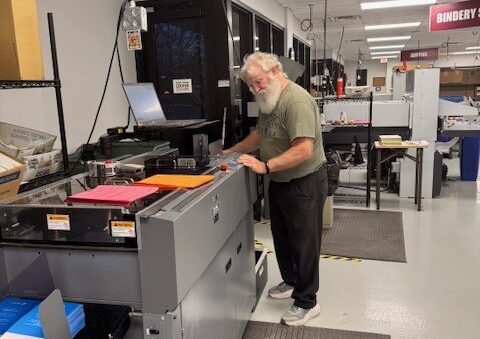

At Columbus, Ohio’s Mount Carmel Health System, automation helps Printing Services keep finishing on track. Operations Manager Carol Stokes says the in-plant now uses two Duplo slitter/cutter/creasers — a DC-648 and a DC-618 — to trim and score the covers of booklets and cut business cards, replacing a slower, more labor-intensive workflow.

“We would take it over to a cutter and we’d have all these cuts because we run the business cards 22-up on a sheet,” Stokes recalls. “Now, we don’t have to do that. We put the sheet in the Duplo, the Duplo cuts it, spits them out, we box them, and we’re good to go.”

The World Bank Printing and Interactive Media teams also automate business card production.

“The old-school way of doing a prepress is super tedious, so we automated that through our prepress software to basically go directly to the press,” says Wes Troup, business solutions associate at the Landover, Maryland-based, in-plant. “Now we’re only actually touching the ones that need some sort of manual intervention: a name, a LinkedIn title, or a Twitter, or something like that.”

Aside from time savings, Stokes explains, automation has reduced errors and streamlined workflows.

“As long as the input is correct from the front end,” she says, “then that speeds up the process all the way through and eliminates some error points that could have occurred in the middle of all these touch points that we don’t have anymore.”

The old-school way of doing a prepress is super tedious, so we automated that through our prepress software to basically go directly to the press. Now we’re only actually touching the ones that need some sort of manual intervention.

— Wes Troup, World Bank

Customer Experience

Mount Carmel Health System has also invested in front end automation — specifically, its digital storefront.

“Everything starts with our storefront system in our shop, and everything ends with it,” Stokes says. “It sounds archaic because everybody nowadays uses that, but when we implemented that, the way we were doing things was ridiculous, and this has just improved everything tenfold.”

The in-plant’s system incorporates tracking, enabling customers to see their job’s production status in real time and, if applicable, whether it’s been shipped.

Up in Canada, McMaster’s Media Production Services also uses a storefront system. Poelmans says the team is trying to push more customers to use it to submit their orders, rather than sending them via email.

As a bonus, he adds that customers can place jobs whenever they have time.

“As much as I would love to add two more customer service people, the storefront sort of acts as one — one that’s open 24/7,” Poelmans says.

AI Fills the Skill Gap

Artificial intelligence (AI) is often part of the conversation around automation, as it can also save time and reduce labor.

The World Bank’s Printing and Interactive Media team makes good use of the Bank’s custom-built, secure AI system which is tailored to terms and processes used within the organization. The in-plant can use internal acronyms and project names to get data and generate reports without having to explain them, streamlining project development and administrative tasks.

Even if your parent organization hasn’t created its own AI system, there are ways to use AI to fill skill gaps. For instance, Licata says AI helps him with graphic design, which he isn’t trained in.

“If I want, say, orange alligators surfing on the side of a mountain, it would probably take me hours to create that, where AI takes 45 seconds — and then it gives me three different options,” he says.

Poelmans is also using AI for graphics, such as a sign for a new residence hall named after former McMaster faculty member and alumnus Lincoln Alexander.

“All we were given is a little photo from the early ’70s, but they wanted that person’s face super big on the sign,” he says. “So we used this [AI] upscaling software to upscale that photo of Lincoln Alexander so he could look great, not so pixelated, and super high res.”

A ‘Force Multiplier,’ Not a Replacement

It’s no secret: Automation and AI can help in-plants short on labor. As Stokes says, “The more you can automate, the better off you are, because that is going to increase productivity. I think it betters your workflow, and I think it’s a lesser learning curve for your staff.”

But the idea that these tools will take jobs from skilled workers? Poelmans doesn’t buy it.

“Some people are worried it’s going to replace a whole bunch of skilled labor,” he says. “But I see it not as a replacement, but as a force multiplier, as a way of amplifying our efforts. If I’m not able to hire 10 more people over the next few years, maybe using AI to augment our output is one strategy to keep growing.”

Troup stresses that investigating automation and AI now — not later — is key.

“This is tough for an in-plant world: Actually carve out time,” he says. “Dedicate at least an hour or two a week — minimum — to finding new things with AI, with automation … If nothing else, you’re immersing yourself in knowing what’s out there.